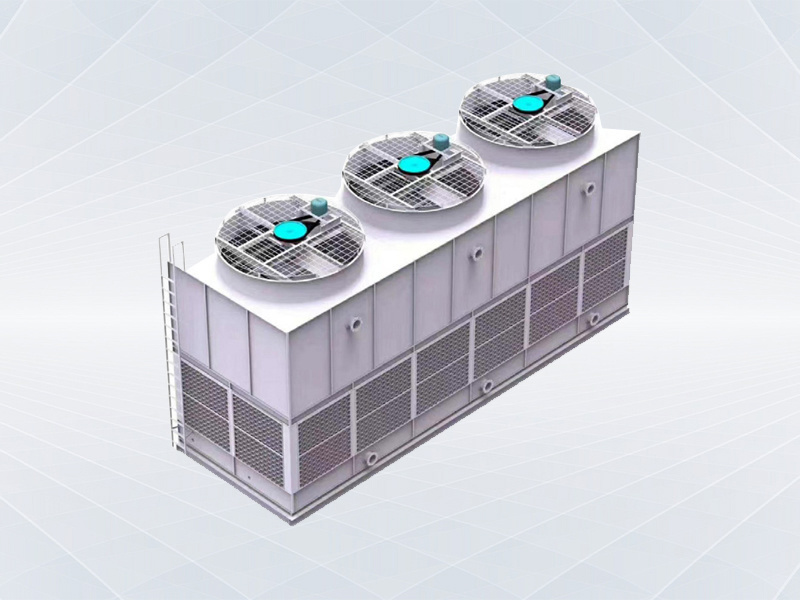

ZSNS water-cooled screw chiller unit

Classification:

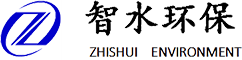

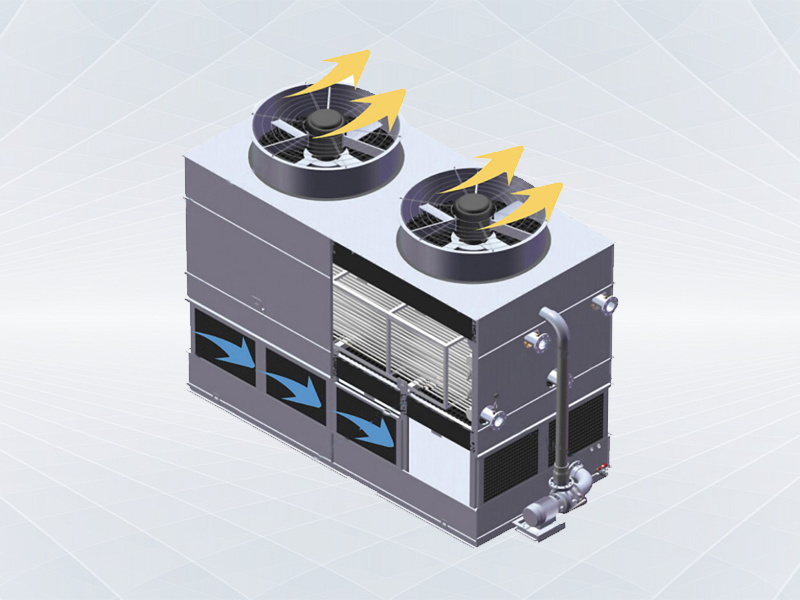

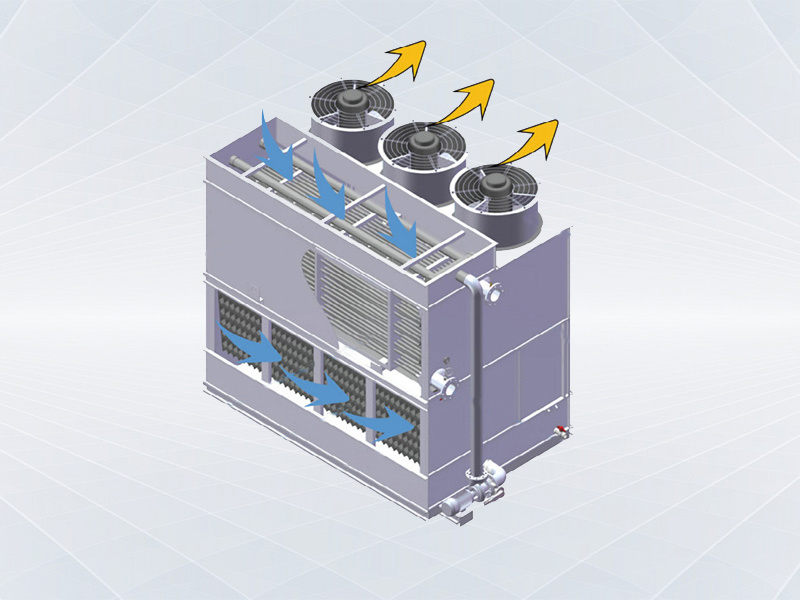

Keywords: closed cooling tower, open cooling tower

ZSNS water-cooled screw chiller unit

Product performance

The water-cooled chiller has a small volume, large refrigeration capacity, and uses imported compressors. It has good low-temperature performance, reliability, and durability. The product is designed according to the characteristics of industrial applications, and is equipped with a low-temperature circulating water pump and a stainless steel freezing water tank, which is easy to use. All materials in contact with water are made of anti-corrosion materials, which can prevent rust and corrosion. The microcomputer LED quantity controller has temperature display, temperature setting, automatic adjustment of freezing water temperature, and compressor delay protection functions. It is equipped with good electrical components such as contactors and relays, and is equipped with complete indicator lights, switches, and easy to operate. It is equipped with an electronic water level indicator and alarm device, and low water level automatic alarm. The operator can control the water level of the freezing water tank through the control panel, timely water replenishment, modular design, and the system of each compressor. Independence, even if one system encounters problems, it will not affect the normal operation of other systems.

1. The compressor of the unit is selected from original imported brands such as Maneurop from France, Copeland/Carrier from the United States, and BITZER from Germany for medium and low temperature compressors;

2. Use refrigerants such as R404A, R410a, R22/R407C, etc. to meet refrigeration temperature and environmental requirements;

3. Temperature selection range: Process chilled water can be provided between -5 ℃ and -60 ℃ (users can choose unit specifications with different outlet temperatures according to different production needs);

4. According to user needs, multiple refrigerants (chilled water) can be selected: alcohol based refrigerants such as ethylene glycol aqueous solution, alcohol, ternary mixed solution, etc. The evaporator can also be designed according to anti-corrosion requirements, using calcium chloride aqueous solution.

Basic parameters

| model | ZSNS | |||||||||||

| 100.1 | 135.1 | 180.1 | 195.1 | 235.1 | 260.1 | 305.1 | 320.1 | 350.1 | 385.1 | |||

| Nominal cooling capacity | KW | 100 | 135 | 180 | 195 | 235 | 260 | 305 | 320 | 350 | 385 | |

| 104Kcal/h | 8.6 | 11.6 | 15.5 | 16.8 | 20.3 | 22.4 | 26.3 | 27.6 | 30.2 | 33.2 | ||

| Run control | PLC programmable controller fully automatic control | |||||||||||

| Power Supply | 380V/3N~/50Hz | |||||||||||

| compressor | type | 5-6 Asymmetric Semi enclosed Twin Screw Compressors | ||||||||||

| quantity | 1 unit | |||||||||||

| startup type | Y- Δ start-up | |||||||||||

| Energy regulation | 0-33-66-100% | 0-25%-50%-75%-100% | ||||||||||

| Input power | KW | 22.6 | 29.8 | 37.3 | 41 | 49.9 | 54.3 | 61.1 | 64.3 | 70.8 | 78 | |

| Rated current | A | 39.3 | 51.9 | 64.9 | 71.3 | 86.8 | 94.5 | 106.3 | 111.9 | 123.2 | 135.7 | |

| evaporator | type | Efficient shell and tube dry heat exchanger | ||||||||||

| Water volume | m3/h | 17.2 | 23.2 | 31 | 33.6 | 40.6 | 44.8 | 52.6 | 55.2 | 60.4 | 66.4 | |

| Pipe diameter | DN65 | DN80 | DN100 | DN125 | ||||||||

| Water pressure drop | Kpa | 48 | 48 | 50 | 50 | 50 | 52 | 54 | 55 | 55 | 58 | |

| condenser | type | Efficient shell and tube heat exchanger | ||||||||||

| Water volume | m3/h | 21.5 | 29 | 38.7 | 41.9 | 50.5 | 55.9 | 65.6 | 68.8 | 75.3 | 82.8 | |

| Pipe diameter | DN65 | DN80 | DN100 | DN125 | ||||||||

| Water pressure drop | Kpa | 46 | 46 | 47 | 47 | 48 | 49 | 51 | 53 | 53 | 56 | |

| Refrigerant | type | R22 | ||||||||||

| Filling amount | kg | 20 | 25 | 30 | 40 | 45 | 49 | 52.2 | 60 | 65 | 75 | |

| External dimensions | long | mm | 2283 | 2495 | 2517 | 2825 | 2822 | 2778 | 2767 | 2750 | 3147 | 3070 |

| wide | mm | 700 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | |

| high | mm | 1489 | 1450 | 1557 | 1570 | 1700 | 1700 | 1850 | 1852 | 1880 | 1890 | |

| The unit is slightly heavy | kg | 850 | 1050 | 1270 | 1340 | 1640 | 1680 | 1720 | 1750 | 2080 | 2300 | |

| Slightly heavy operation | kg | 900 | 1150 | 1420 | 1540 | 1890 | 1940 | 1990 | 2050 | 2330 | 2550 | |

Note: Parameter changes caused by equipment modifications are subject to no further notice, and the specific parameters will be based on our plan.

-The parameters in nominal operating conditions are as follows: chilled water inlet/outlet temperature 12 ℃/7 ℃; Cooling water inlet/outlet temperature 30 ℃/35 ℃;

-Temperature conditions: The outlet temperature range of chilled water is 5 ℃ to 15 ℃, and the inlet temperature range of cooling water is 19 ℃ to 33 ℃;

-The water side design of the evaporator and condenser is designed to withstand a pressure of 1.0 MPa;

-In nominal operating conditions, the fouling coefficient on the water side of the evaporator is 0.018m2 ℃/kW, and the fouling coefficient on the water side of the condenser is 0.044m2 ℃/kW;

-In addition to the above specifications and requirements, the company can provide non-standard products according to customer requirements.

Related Products

Online consultation